About Us

About Me

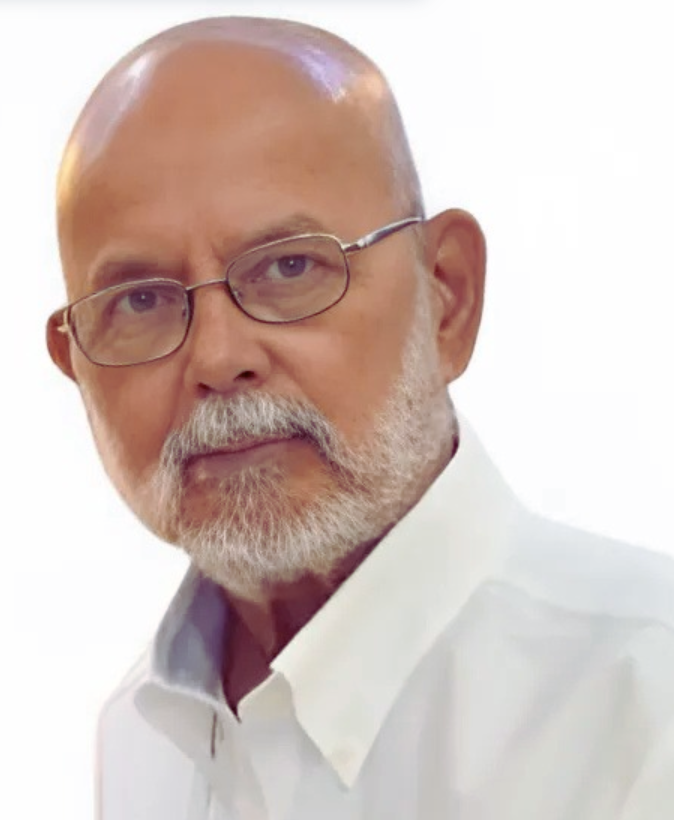

Mr. C.V. Satam

Mr. C.V. Satam is Mechanical Engineer. He started his career with Indo Berlin Industries who supplied the major plants to HOC Ltd. around 1970. He subsequently worked for manufacturers like G.R. Engineering & Lloyds Steel Industries Ltd. He has also worked with well-known consultants like Tata Consulting Engineering and Simon Carve India Ltd.

Mr. Satam has diversified experience in the equipment industry. He has worked on Chemical, Petrochemical, Fertilizers, Nuclear Power, Thermal Power, Pharmaceuticals and Polyester Fiber Industry. He has been involved with marketing and sales, mechanical design, process design, estimation, purchase planning, production planning, production & quality control plant maintenance and ISO-9000 documentation.

Mechanical design of equipment is Mr. Satam’s specialty. He has knowledge of all national and international codes. Besides codes, he can design any component of equipment for the desired loading. Apart from primary stresses, he is also well versed with secondary stresses like local stress, Discontinuity, thermal stress, fatigues and creeps analysis. He has also studied modern analytic methods including Finite elements and is well versed with latest computer packages.

Mr. Satam was also Deputy General Manager of Lloyds Steel Prior to promoting the firm. Apart from equipment, he also built India’s first indigenous steering gear for the Washer’s while in Lloyd Steel. Mr. Satam has also worked extensively on the software developments for the equipment industry. He has developed more than 50 programs in design.

Mr. Satam has published several papers in design. He was on the faculty of PPMAI, VJTI and Institution of Mechanical Engineers. He has won 5 Gold Medals from the Institute of Engineers. Mr. Satam was also an external examiner to the University of Bombay.

Mr. Satam designed and engineered Indias first auto matic rail loading system for ONGC while in Lloyds Steel with assistance from FMC-France.

He promoted Process Equipment Engineering and Elgin Process Equipment Pvt. Ltd, which supplies:

- Air Drying Plants.

- Liquid Drying Plants.

- Low Pressure Dehumidifie

- Liquid Benzene Dryer (with Udhe and UOP for Nirma ltd.)

He also designed and engineered Indias and Asia’s first Benzene Vapour Recovery System in 2002, which won an international award. He supplied off gas dryer to ONGC through Duke- offshore and Burn Std. Co. In 2005 along with IIT and Clique Development Consultant was instrumental in designing equipment for India’s largest Solar Water Heating System to Mahananda Dairy at Latur Road.

He was felicitated by Thane Belapur Industries Association for his contribution to installing large common effluent treatment plant of Navi Mumbai.

Mr. Satam has also traveled abroad to receive management training.

MEMBERSHIPS:

- PPMAI

- Institution of Engineers

- Indian Welding Society

10,000+

Successfully Student Trained

3,000+

Students Successfully Placed in Jobs

600+

Successfully Project

45+

Year of experience

About Founders

Our Proud Achievements

RECEIVING GOLD MEDAL

FROM VICE PRESIDENTS OF INDIA SHRI B.D.JATTI.

RECEIVING GOLD MEDAL

FROM VICE PRESIDENTS OF INDIA SHRI B.D.JATTI.

ᴄʜᴀɪʀᴍᴀɴ & ʙᴏᴀʀᴅ ᴏꜰ ᴅɪʀᴇᴄᴛᴏʀꜱ

of COMMON EFFLUENT TREATMENT PLANT (THANE-BELAPUR) ASSOCIATION

ᴅɪʀᴇᴄᴛᴏʀ ᴍʀ. ᴄ.ᴠ. ꜱᴀᴛᴀᴍ

ᴡɪᴛʜ ᴍʀ. ᴀʀᴜɴ ᴋᴀʀᴀɴᴅᴇ, ᴍᴀɴᴀɢᴇʀ

ᴘʀᴏᴄᴇꜱꜱ ᴛᴇᴄʜɴᴏʟᴏɢʏ ɪɴ ꜰʀᴏɴᴛ ᴏꜰ ᴛʜᴇ ᴘʟᴀɴᴛ

Sustainability

We Follow Best Practices

At Equipment Design, we are committed to maintaining the highest standards in everything we do. Our approach is guided by

We Uphold Excellence to Ensure Student Success

we are dedicated to helping students achieve their goals through:

- Comprehensive Curriculum

- Experienced Mentors

- Hands-On Training

- Continuous Support